Multifunctional Ultrasonic Cleaners in Laboratory Use: Expanding Horizons in Scientific Applications

With its diverse functionality and high efficiency, the multifunctional ultrasonic cleaner has become an indispensable tool in laboratory settings. Beyond traditional apparatus cleaning, it plays a crucial role at various stages of experimentation, such as degassing, emulsifying, mixing, and extracting. These devices challenge conventional methods, offering the precision and versatility required in modern experiments.

Laboratory Cleaning and Application Areas

One of the primary uses of multifunctional ultrasonic cleaners in laboratories is to provide efficient cleaning services. For test tubes, beakers, crucibles, and other laboratory glassware, ultrasonic cleaning guarantees cleanliness without damaging the materials. Its working principle involves using ultrasonic vibrations to generate cavitation effects in liquids, which rapidly remove micro-contaminants adhering to the surfaces of objects.

Additionally, ultrasonic technology finds wide-ranging applications during experiments by leveraging its unique physical and chemical properties. Ultrasonics can facilitate chemical reactions, aid material dispersion, and break cell structures. Its low energy consumption and pollution-free advantages make it increasingly popular in chemical, physical, and biological experiments.

Specific applications include:

1. Efficient Cleaning: This is the fundamental function of multifunctional ultrasonic cleaners, effectively removing dirt, residues, and microorganisms from various laboratory ware, ensuring cleanliness and safety. Ultrasonic cleaning reaches into the most intricate parts of equipment, cleaning more thoroughly than manual methods, thereby enhancing the accuracy and safety of experiments. Different ultrasonic frequencies can be optimized for various materials and types of contaminants.

2. Sample Preparation: Many experiments require pre-treatment of samples, such as dispersion, emulsification, and homogenization. Multifunctional ultrasonic cleaners effectively handle these tasks, for example:

- Cell Disruption: The cavitation effect of ultrasonics can efficiently break cell walls, releasing intracellular substances for subsequent analysis and extraction.

- Nanomaterial Synthesis: Ultrasonic-assisted synthesis produces nanomaterials of various sizes, shapes, and structures, widely applicable in material science and chemistry.

- Extraction: Ultrasonic-assisted extraction enhances extraction efficiency and reduces solvent usage, making it more environmentally friendly and effective.

3. Chemical Reaction Assistance: Ultrasonics can facilitate numerous chemical reactions, for example:

- Accelerating Reaction Rates: The cavitation effect increases the contact area between reactants and mass transfer efficiency, thereby accelerating reaction rates.

- Increasing Reaction Yields: In certain reactions, ultrasonics can increase yields, producing higher amounts of the desired products.

- Synthesis of New Materials: Ultrasonics can be used to synthesize new materials that are challenging to produce with traditional methods.

4. Other Applications: Multifunctional ultrasonic cleaners can also be used for degassing, mixing, homogenizing, and assisting special experimental processes such as ultrasonic-assisted precipitation and ultrasonic-assisted catalytic reactions. Their controllable frequency, power, and time settings ensure precision and reproducibility in experiments.

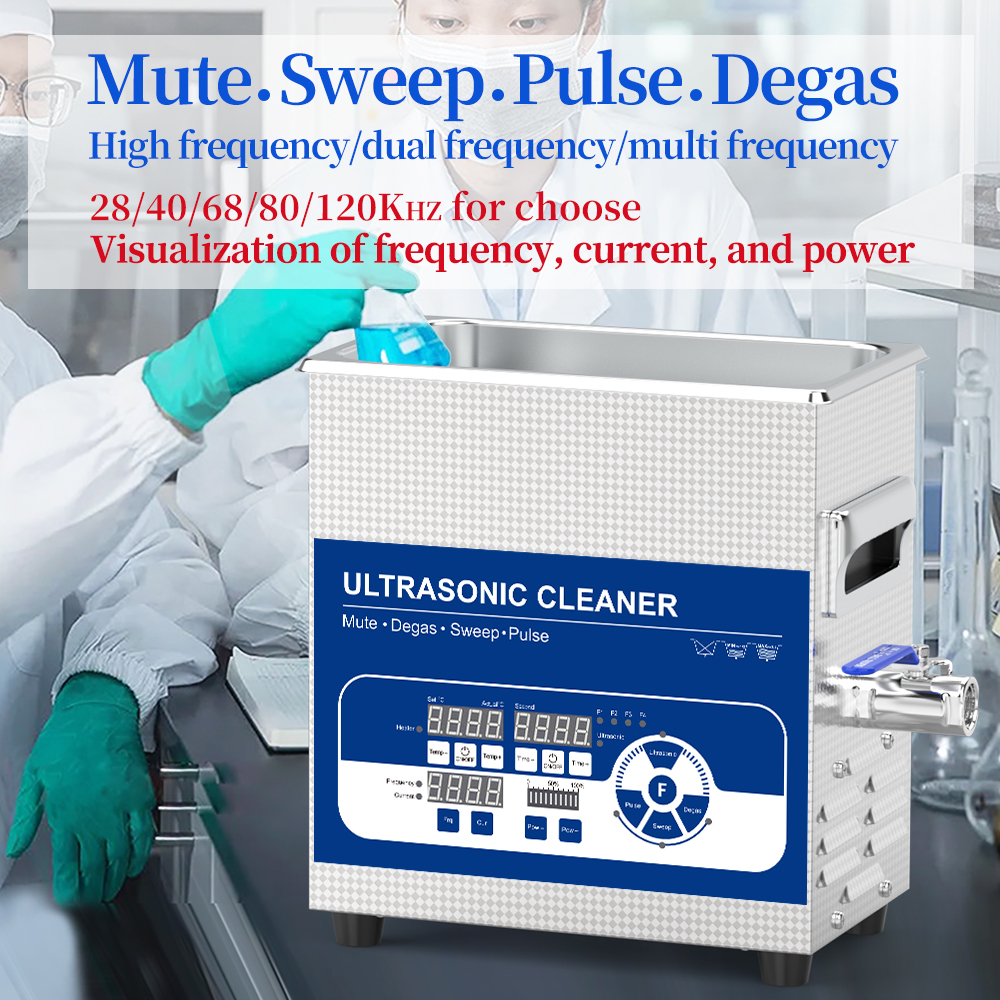

Frequency and Functionality: Flexible Operational Experience

Multifunctional ultrasonic cleaners often come equipped with multi-frequency adjustment features, including single, dual, and triple-frequency devices. By simply adjusting the controls, experimenters can switch frequencies to meet different experimental needs. For instance, low frequencies are suitable for large pieces or coarse washing, while high frequencies are ideal for more delicate cleaning. Additionally, precise second-based time controls provide scientific rigor and assurance in experiments.

In chemical experiments, ultrasonics' unique physical effects are not limited to synthesis and degradation processes but also enhance mixing and mass transfer efficiency, excelling in benign chemical processing. The vibration effect of ultrasonics can break through the boundary layers of traditional reactions, significantly enhancing chemical processes.

Innovative Chemical Processing Solutions

In the realm of chemistry, the role of ultrasonic cleaners extends beyond cleaning to chemical synthesis and degradation applications. Ultrasonic synthesis technology leverages cavitation effects to create extreme conditions momentarily, producing nanomaterials with special properties. These materials are in high demand in modern industry and research for their efficiency and environmental benefits. Likewise, ultrasonic degradation technology offers an economic and effective solution for treating complex compounds and even wastewater.

Using multifunctional ultrasonic cleaners in the laboratory can effectively enhance various experimental metrics, offering numerous innovative possibilities and a wide range of auxiliary functions for researchers. Their unique ultrasonic effects unlock countless potentials.