Auto Parts Cleaning

The Role of Ultrasonic Cleaner in Automobile Components

In the automobile manufacturing process, the pollutants adhering to the surface of automotive precision metal parts are processing chips metal, dust, oil and various lubricating oils, coolants, grinding and polishing compounds, etc. used in the processing process, of course, due to more processes, including workshop dirt, imprints, finger grease, etc. The presence of these contaminants greatly reduces their precision and seriously affects the process of automobile production and manufacturing.

With the advancement of science and technology and the development of the automobile maintenance industry, some new technologies, new processes, new materials and new equipment have emerged in automobile maintenance and repair. They can not only improve the maintenance speed and quality of the car, but also enhance the reliability of the car, extend the service life of the car, and at the same time reduce the consumption of car maintenance, reduce the maintenance cost, so that the enterprise can get high economic benefits.

When car maintenance needs to clean parts, the purpose is to inspect and classify parts, so as to find damage to parts and repair them in time; The second is to ensure the quality of maintenance and assembly.

The perfect combination of the physical cleaning effect of ultrasonic technology and the chemical action of the cleaning medium, and the optimal selection of ultrasonic frequency band and power density, can fully and thoroughly clean the internal and external oil, carbon deposits, gum and other dirt of various parts.

The technical principle of ultrasonic cleaning technology

The sound wave with frequency higher than 20KHZ is called ultrasonic. The propagation of sound waves is also a way of energy transfer. There are tiny bubbles (cavitation nuclei) in the liquid, and when ultrasonic waves are alternately generated in the form of positive pressure and negative pressure (the frequency of alternation is tens of thousands of times per second), these small cavitation nuclei will grow rapidly in the negative pressure area due to the sudden generation of negative pressure, and will rapidly close and rupture in the positive pressure area due to the sudden generation of the positive area, which is ultrasonic cavitation.

Cavitation can concentrate the energy of the sound field, and with the moment of the collapse of the cavitation bubble, its highly concentrated energy is released in a very small space of the liquid, forming an unusual high temperature (> 4000 °C) and high pressure (>5×107Pa). When the cleaned workpiece is immersed in the cleaning solution, ultrasonic waves act on the inner and outer surfaces of the workpiece with a strong cavitation effect, so it is particularly suitable for complex porous smooth surfaces that cannot be scrubbed by hard objects.

Two Key Points for Ultrasonic Cleaning

1: Selecting the suitable ultrasonic cleaner

There are many ultrasonic cleaning machines with many specifications and functions on the market. When you are ready to decide to buy one, there are some considerations that you should keep in mind.

- Number and size of parts you want to clean and the degree of contamination to be removed

- Cleaning time and frequency

2: The placement of cleaning accessories

Stacking many spare parts in the washing basket and immersing them in the washing tank will not only lead to unsatisfactory cleaning results, but may also lead to damage to parts. The following are the reasons:

The ultrasonic action is the cavitation effect caused by the generator-driven transducer at the bottom of the cleaning tank, which is transported upward to the surface of the spare part by the cleaning fluid and then reflected back. If the parts are stacked on top of each other, they will not have full access to the cleaning fluid. Therefore, it is necessary to arrange the parts as small and orderly as possible so that the surface of the accessories can contact the cleaning fluid in a large area!

Caution: Do not soak your hands directly in the cleaning troughs when placing the cleaning accessories, high temperatures and high-frequency vibrations can cause damage to skin and bones. Wear gloves!

The cleaning of the traditional automotive industry generally uses high-pressure water, plus various chemical solvents and cleaning agents to complete the cleaning operation, which not only wastes a lot of water resources, but also cleans down the dirt impurities and sewage containing chemicals, destroying and polluting the environment. The ultrasonic cleaning machine adopts the combination of the physical cleaning effect of ultrasonic technology and the chemical effect of the cleaning medium to improve the selection of ultrasonic frequency band and power, and realize the full cleaning of oil, carbon accumulation, glue and other dirt inside and outside each component, so as to achieve the requirements of high efficiency and cleanliness.

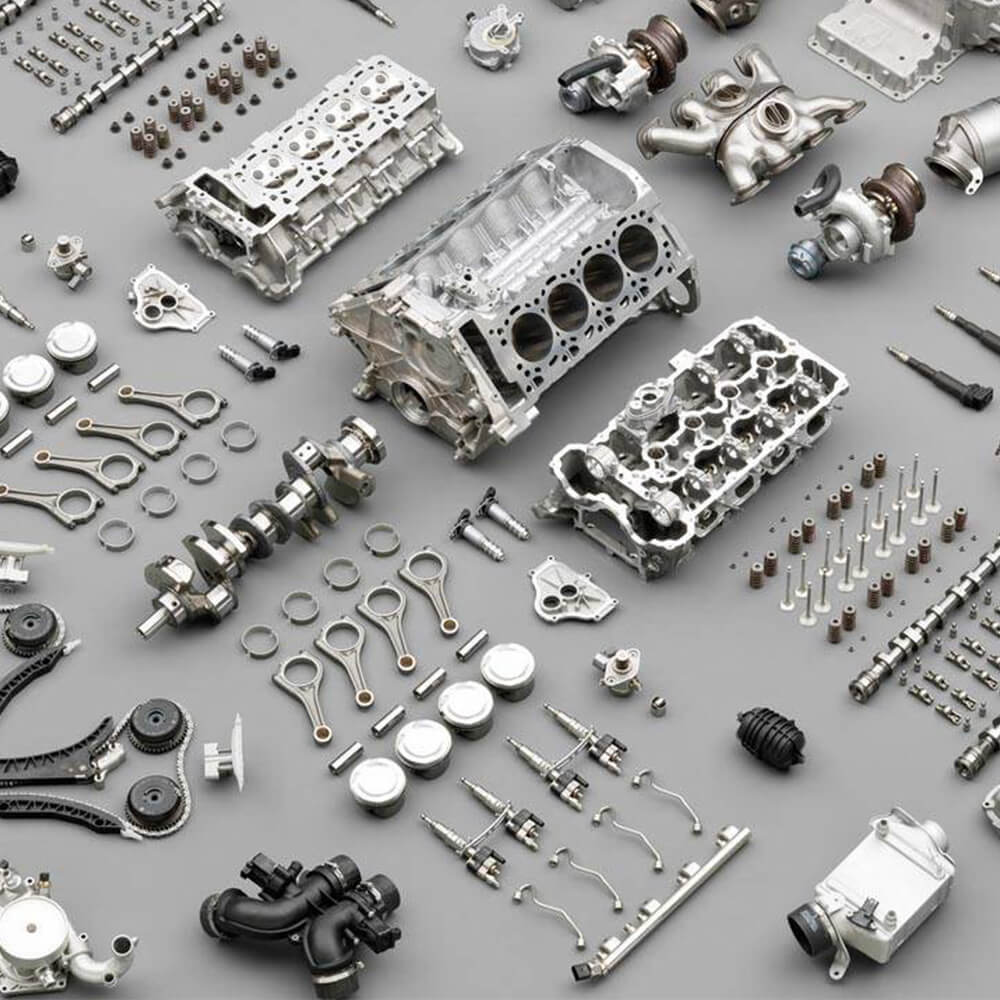

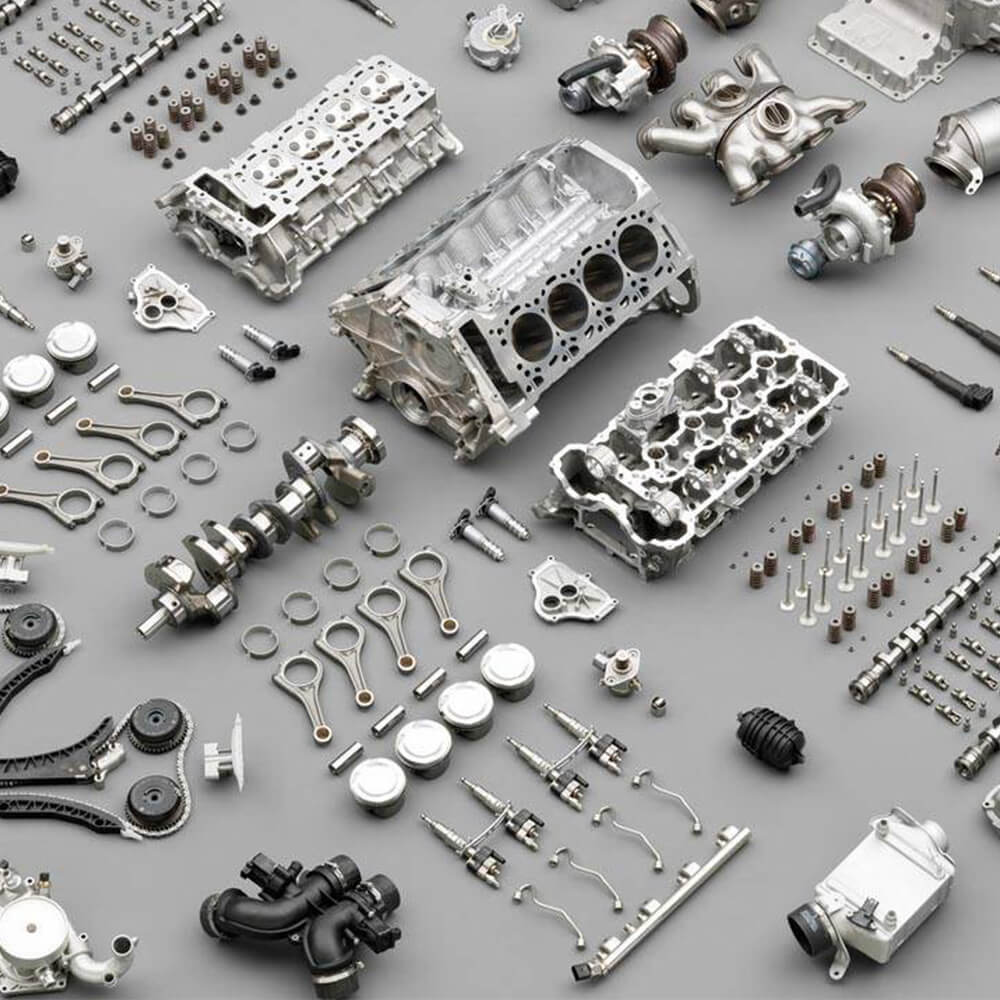

The Cleaning Range of Ultrasonic Cleaners

The cleaning of oil, iron filings and dust during the production and assembly of automobiles, such as carburetors, cylinder blocks, steel rings, tires, front axles, rear axles, swing arms, ball heads, coil springs, valve bodies, transmission shafts, hubs, crankshafts, bearings, transmission gears, spark plugs, oil nozzles, pressure plates, clutch plates, vacuum boosters, pistons, headlights, door mirrors, sensors, shock absorbers, water pumps, water pipes, radiators, air conditioners, motors, compressors, and so on

Utilizing the Ultrasonic for Cleaning Automobile Components

Using ultrasonic cleaning to speed up the cleaning of almost all parts we come into contact with in cars, motorcycles or trucks, we have listed some of the more common parts:

Carburetor——this is clearly the first choice for ultrasonic cleaning. The small needle valves, nozzles, orifices and ports that make up the carburetor all require laborious removal of adherent fuel and sludge. To make matters worse, traditional cleaning often damages these fragile surfaces, which can further slow down work and can affect the vehicle’s performance if not repaired properly.

Cylinder cover——cleaning the cylinder head from fuel, varnish, sludge and carbon deposits is very tedious, especially around the intake and exhaust ports. Ultrasonic cleaning can turn this lengthy process into a 30 to 40 minute process, making dye penetration testing and reassembly a breeze.

Brake cylinders——as brake cylinders wear out, pistons and blocks tend to be filled with dirt, dust, and metal particles. Improper cleaning can lead to piston hangouts and brakes that do not work. Ultrasonic cleaning removes all debris from the surface of the fittings and thoroughly cleans the reservoir.

Injectors——cleaning injectors by hand is much like cleaning a carburetor, which is a time-consuming process and can easily damage surfaces or scratch injectors, resulting in inefficient fuel injection and poor performance. Soaking the injector in a solvent to dissolve the varnish will help, but the port still needs to be cleaned to allow all deposits to drain from the opening. Ultrasonic cleaners make this task easy.

Differential mechanism——cleaning gear oil from the differential box often requires the use of dangerous chemical solvents and leaves residue that makes it difficult for new bearings and seals to fit fit. Ultrasonic cleaning leaves a shell that looks brand new, and ring gears and pinions can be cleaned for penetration cleaning and tooth cleaning.

These are just some of the common components that ultrasonic cleaners can clean quickly. We can easily incorporate transmissions, alternators, fuel pumps, and particle traps. Regardless of parts or components, the liquids used in the vehicle and the deposits left behind by the use can be removed quickly and thoroughly, making ultrasonic cleaners the best tool in car maintenance and repair.