Multifunctional Ultrasonic Cleaners in Laboratory Use: Expanding Horizons in Scientific Applications

With its diverse functionality and high efficiency, the multifunctional ultrasonic cleaner has become an indispensable tool in laboratory settings. Beyond traditional apparatus cleaning, it plays a crucial role at various stages of experimentation, such as degassing, emulsifying, mixing, and extracting. These devices challenge conventional methods, offering the precision and versatility required in modern experiments.

Laboratory Cleaning and Application Areas

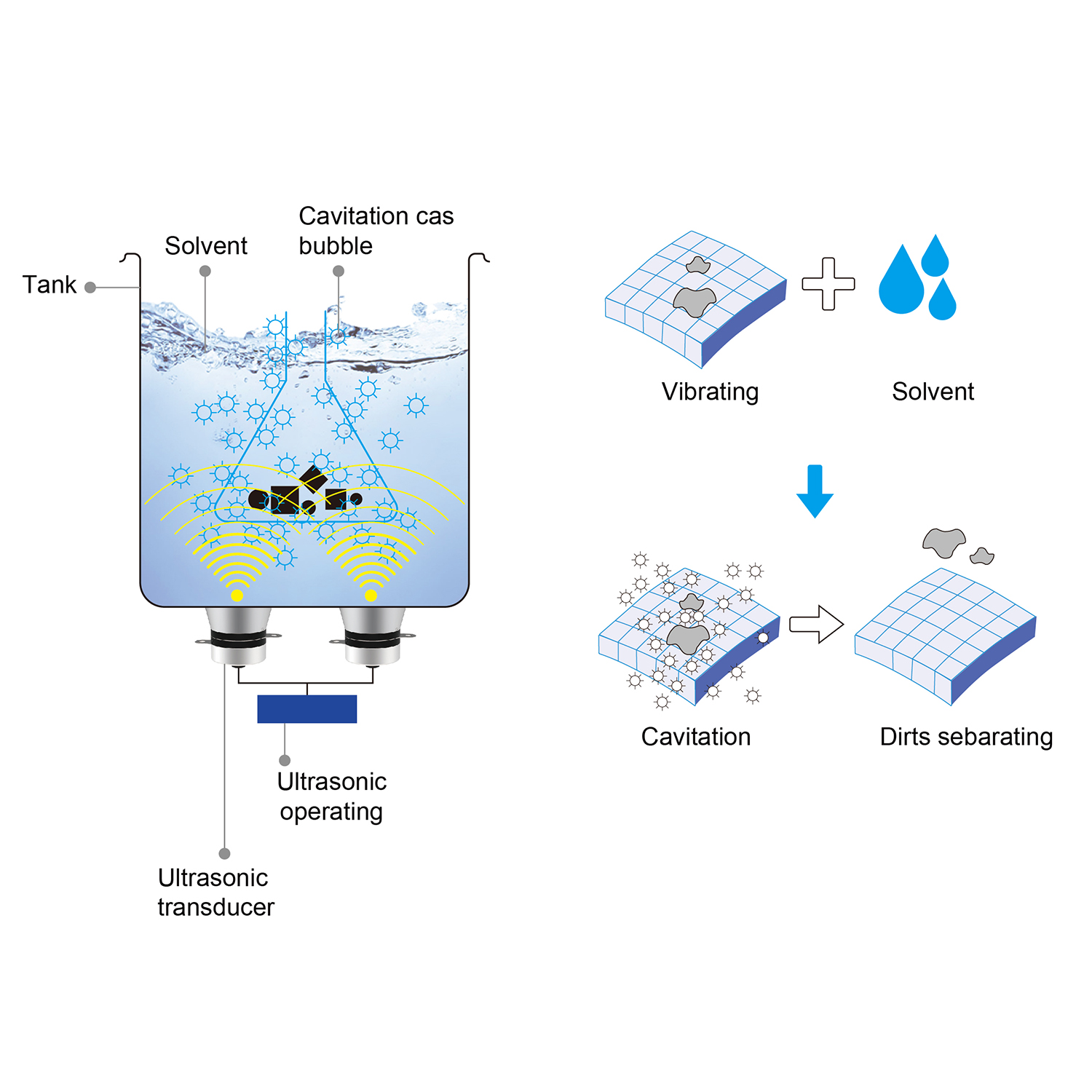

One of the primary uses of multifunctional ultrasonic cleaners in laboratories is to provide efficient cleaning services. For test tubes, beakers, crucibles, and other laboratory glassware, ultrasonic cleaning guarantees cleanliness without damaging the materials. Its working principle involves using ultrasonic vibrations to generate cavitation effects in liquids, which rapidly remove micro-contaminants