Glasses/Optical Cleaning

The Cleaning of Optical Components

Utilizing Ultrasonic Cleaners to Clean Optical Components

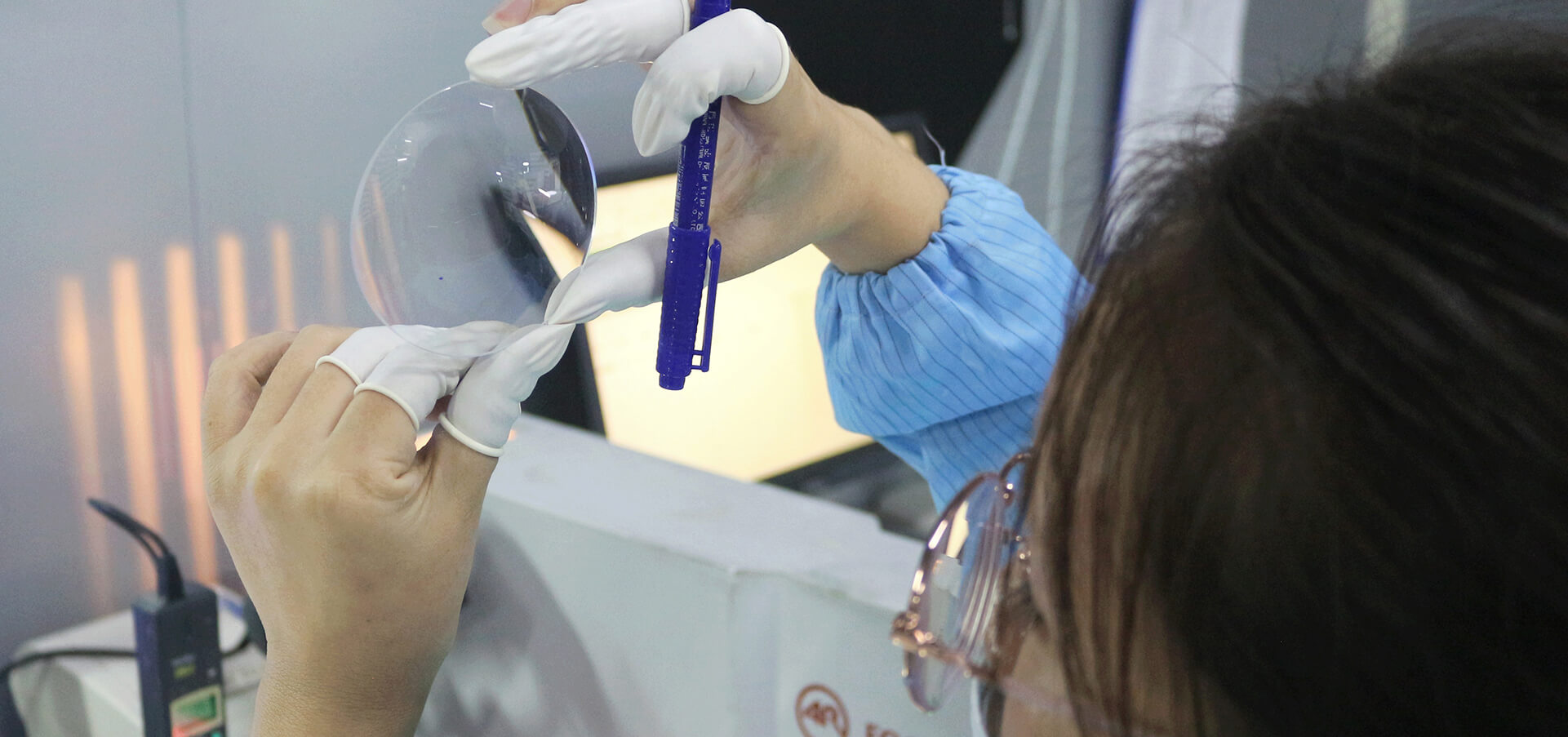

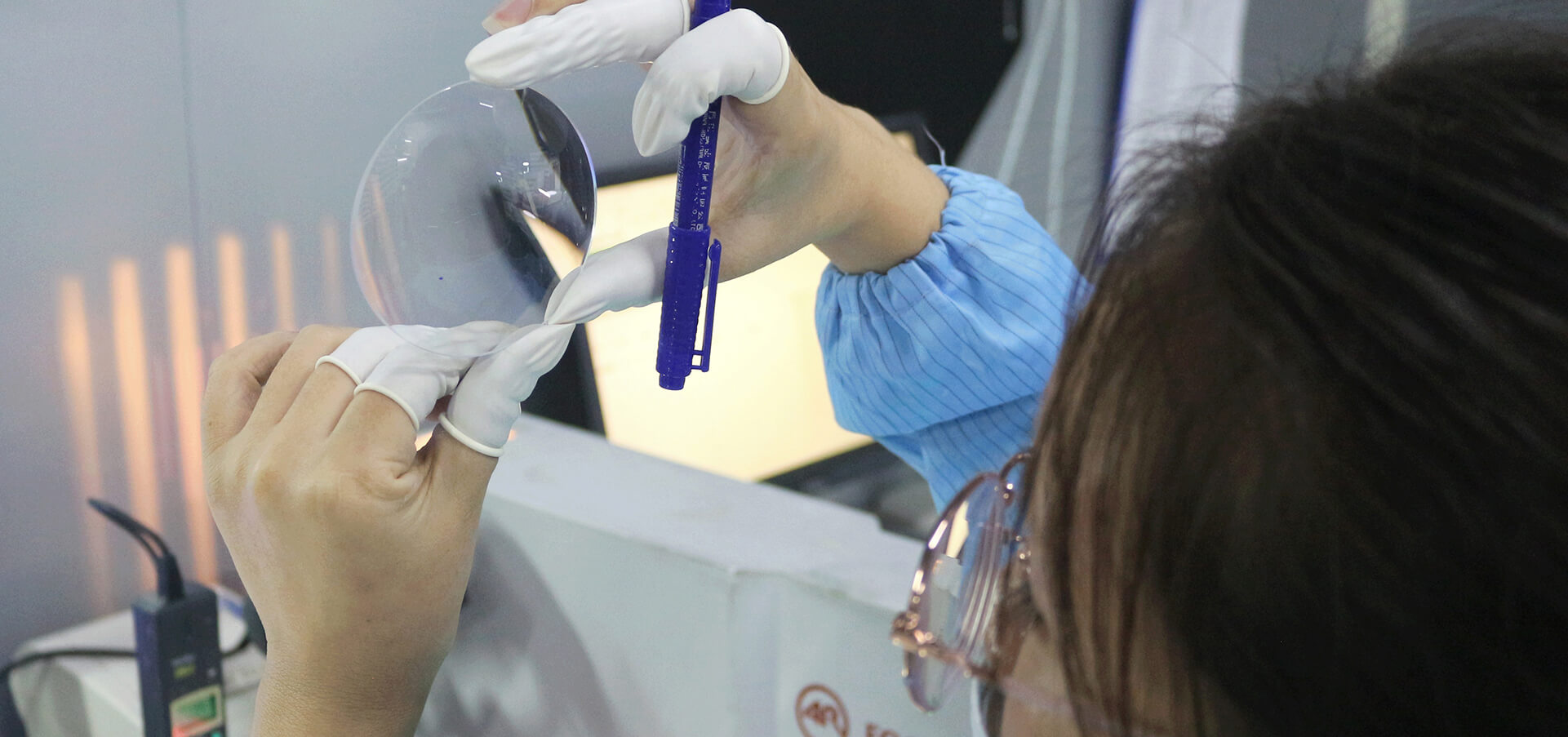

In optical cold working, the cleaning of lenses mainly refers to the residual polishing liquid after lens polishing. Binder. Cleaning of protective materials: Lens edging and edging oil. cleaning of glass powder; Cleaning of finger prints, saliva rings and various adhesions before lens coating. The traditional cleaning method is to use wiping materials (gauze, dust-free paper) and chemical reagents (gasoline, ethanol, acetone, ether) to soak, wipe and other means for manual cleaning. This method is time-consuming, laborious, and has poor cleanliness, which is obviously not suitable for the modern large-scale optical cold processing industry. This forced people to look for a mechanized cleaning method instead. Therefore, ultrasonic cleaning technology gradually entered the optical cold processing industry and showed its talents, further promoting the development of the optical cold processing industry.

Principle Of Ultrasonic Cleaning Technology

The basic principle of ultrasonic cleaning technology can be roughly considered to be the use of the huge force generated by the ultrasonic field. In cooperation with the washing medium. A method of promoting a series of physical and chemical changes in substances to achieve the purpose of cleaning

When the high-frequency vibration higher than the sound wave (28 to 4OKHz) is transmitted to the cleaning medium, the liquid medium produces a nearly vacuum cavity bubble under the high-frequency vibration, and the cavity bubble collides and merges with each other. In the process of dying. It can make the liquid locally instantaneously generate a pressure of several thousand atmospheres. Such a large pressure causes a series of physical and chemical changes in the surrounding matter. This action is called “cavitation effect”:

1. Cavitation effect can break the chemical bonds of material molecules, causing various physical changes (dissolution, adsorption, emulsification, dispersion) and chemical changes (oxidation, reduction, decomposition, synthesis and so on);

2. When the natural frequency of the cavity and the ultrasonic frequency are equal. It can generate resonance, and a large amount of heat energy is accumulated in the resonant cavity bubble, which is enough to break the chemical bonds of the surrounding material and cause physical and chemical changes

3. When cavities are formed, the two bubble walls cause discharge due to a huge potential difference, resulting in the activation of bubbles in the cavity and the activation of surrounding substances, so that the material undergoes physical and chemical changes.

So, in optical cold working, how does ultrasonic cleaning achieve the purpose of cleaning? Generally speaking. The cleaning process is mainly named in the way of drying, such as the iPA process, which refers to the cleaning process of dehydration and drying using IPA (isopropanol) steam, and the pure water process refers to the cleaning process of drying by using hot me small k early lifting or cold pure water spin-drying. Of course, there are other ways to behave. After continuous changes and development, the cleaning process in optical cold working is mainly based on IPA process and pure water process. The IPA process consists of four processes: washing. Rinse, dehydrate, dry.

The Application of Ultrasonic Cleaner in Optical Component Instrument

Ultrasonic optical component cleaning machine is mainly used in: glass lenses, plastic lenses, microscopes, telescopes, camera lenses, coated glass, prisms, lenses and other optical products before and after coating and pre-assembly process cleaning; In the optoelectronic industry, it is mainly used in ITO conductive glass, LCD substrate cleaning, and residual liquid crystal cleaning after liquid crystal packaging.

Cleaning workpieces: optical glass such as projectors, rear-projection TV, digital cameras, car mirrors and so on

The Selection of Clean-Out Fluid for Ultrasonic Vinyl Record Cleaning

- Utilizing alkaline, neutral water-based cleaning agent, DI water, IPA and other cleaning liquids are used for cleaning, rinsing, drying.

- Equipped with filtration circulation and freezing system to effectively prevent IPA volatilization and reduce costs.

- Each trough cleaning is equipped with an up-and-down throwing system, which makes the cleaning effect more uniform

- Adopting high-sensitivity fireproof and anti-vandal system, which is safer and more reliable.

- Equipped with overload protection such as freezing, filtering, throwing and so on, to ensure the safe operation of the whole machine.

- The ultrasonic adopts a submersible vibrating device for easy maintenance and replacement.

- Stainless steel materials, parts and components are all high-quality imported parts.

- High-performance cleaning equipment can be customized according to the customer's cleaning requirements

The Major Technical Parameters for Granbo Ultrasonic Optical Component Cleaners:

- The ultrasonic adopts a generator with an efficiency of up to 95 percent, and the power is adjustable from 10 to 100 percent;

- Adopting 40KHZ, 68KHZ, 132KHZ and other high-frequency ultrasonic frequencies;

- The unique slow-pull dehydration and circulating hot air drying method replaces traditional solvent dehydration, which is safe and environmentally friendly;

- Equipped with filter circulation system;

- Multi-slot ultrasonic cleaning process to ensure the cleaning effect;

Tips

Because the washing process is divided into solvent cleaning and water-based cleaning. So there are different processes: solvent cleaning, solvent steam drying followed by water-based cleaning. Solvent cleaning is also performed first. Then the solvent is dissolved with an emulsifier, and then water-based cleaning is carried out. Obviously, the latter is smoother in the process. Compact. The requirements for the equipment are also simple. After washing, the surface of the lenses will no longer have strong dirt, only some mixture of cleaning agents and loose dirt.

It is known to all that inorganic optical glass is a supercooled molten state substance with no fixed molecular structure, and its structural formula can be described as a network of silica and certain metal oxides. Its skeleton structure is a silicon-oxygen covalent bond with a large bond energy, and the periphery is an ionic bond formed by oxygen and metal ions with small bond energy and easy breakage. During washing, due to the combined action of ultrasonic field and chemical lotion, some materials with low siloxy bond content or particularly small peripheral bond can easily change during the cleaning process, resulting in poor washing effect. Therefore, choose a lotion with mild performance, suitable lotion concentration, and temperature. Ultrasonic power and washing time are very important to ensure the cleaning quality of lenses.